Against throwaway culture

We fight throwaway culture by developing circular solutions and reducing our emissions. We are committed to adjusting our operations in line with the 1.5 °C climate target, and we regularly monitor the progress of our targets.

Circular economy

We are against throwaway culture. We develop circular solutions to extend the joy our products and services bring and to minimize the strain on our planet.

Circular business models create value by keeping products and materials in circulation instead of discarding them. For us, circularity can be renting, recycling, reusing, repairing, repurposing – the only limit is our creativity.

Our design is created to last. We want to attract people with unique visual appeal, unparalleled quality, and extraordinary attention to detail. We want to make sure our products are never thrown away.

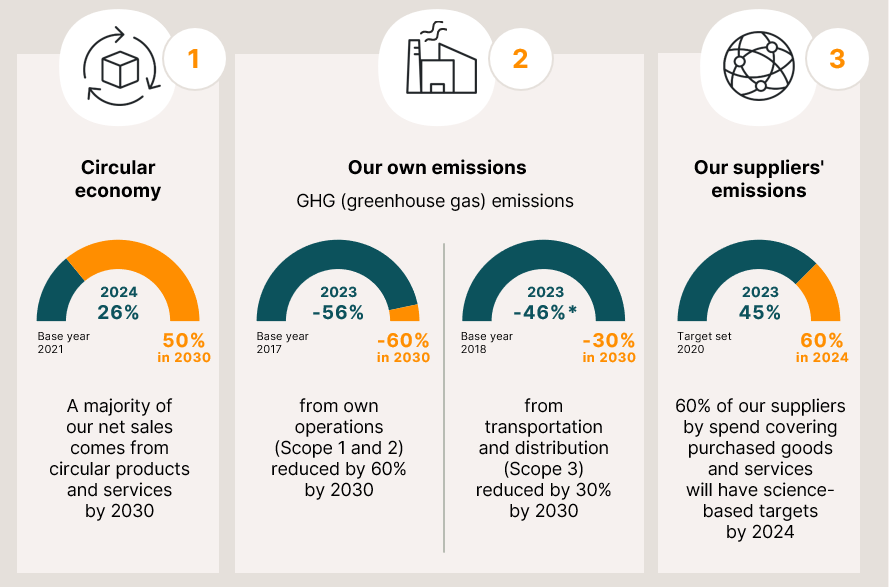

Our target: Our target is that the majority of our net sales comes from circular products and services by 2030. At the end of 2024, 26% of the Group’s net sales were generated from circular products and services.

Climate

Combatting climate change is everyone’s responsibility, and we are ready to do our part – globally, and locally in the communities in which we operate.

In 2020, we joined the UN Business Ambition for 1.5 °C initiative. The initiative encourages companies to set emission reduction targets to stop global warming to 1.5 degrees Celsius. The campaign is led by Science Based Targets Initiative together with Global Compact and the We Mean Business coalition. International standards and guidelines, such as ISO 14001, set an important foundation for our climate management, and our science-based targets have been approved by Science Based Targets Initiative.

Most of the emissions in our value chain are generated in the production of purchased goods and services. Other significant sources of emissions are upstream transportation and distribution, employee commuting and business travel. We actively monitor our energy efficiency and our emissions and take action, with the aim of becoming carbon neutral in the near future.

Our targets for 2030:

• We will reduce the greenhouse gas emissions from our own operations (Scope 1 and 2) by 60 per cent from the base year 2017 by 2030.

• We will reduce greenhouse gas emissions from transportation and distribution (Scope 3) by 30 per cent from the base year 2018 by 2030.

• In terms of spend covering purchased goods and services, 80 per cent of our suppliers must have science-based targets by 2029 (target updated Q1/2025).

Biodiversity

Our business depends on nature and natural resources. Our visionary designers have sought inspiration from nature, and many of our products include materials that come from nature. Protecting the environment and preserving biodiversity are our responsibility, and essential for our future.